PHASEYE - S

- Water-cooled plate detection.

- Wind turbine blade inspection.

- Pull Extrusion Plate Testing

- Composite material testing.

- HDPE pipe inspection

- Honeycomb bonding inspection

- Bolt inspection

- New energy battery testing

- Train wheel and axle

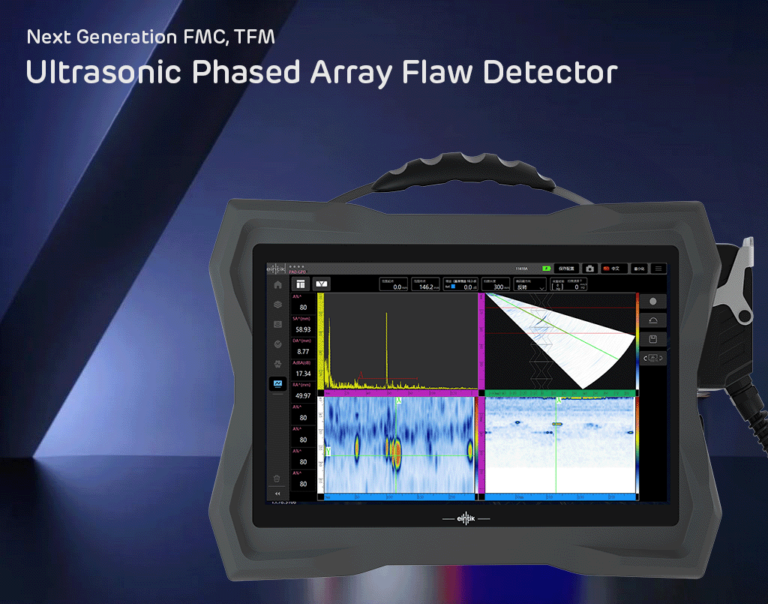

PHASEYE S - Lighter, Portable, Yet Powerful.

The Latest Generation of High-Performance Ultrasonic Phased Array Flaw Detector

The Phaseye S continues the design style of its predecessor, offering simple and convenient operation. Its settings allow for a guided operation mode, providing both ease of use and the flexibility to rapidly adjust parameters as needed. Compact and lightweight, the Phaseye S boasts a small size without compromising its large display, ensuring optimal viewing. Equipped with robust hardware, it features powerful phased array capabilities, supporting A-scan, sectorial, and linear scanning modes. It also offers single-beam and fused C-scan and D-scan displays, along with TOFD scanning modes, capable of simultaneously displaying TOFD and phased array images. With 32 independent channels and compatibility with up to 64-element probes, the Phaseye S meets the diverse requirements of various industries, making it ideal for field inspections where portability is essential.

Detector Highlights:

- Supports a maximum amplitude of 800%, maintaining signal integrity without overflow, even in highly sensitive detection scenarios.

- Features advanced ACG/TCG functionality, including manual TCG, independent and simultaneous ACG/TCG recording.

- Equipped with self-diagnosis capabilities for real-time testing of both probe and instrument status.

- Boasts a powerful interface wave tracking function, with TCG position dynamically adjusting in real time based on the interface wave.

- Enables remote operation control through a wireless remote controller, providing flexibility in field environments.

- Offers a flexible custom view layout, allowing customization of the best view mode according to specific inspection application requirements.

PHASEYE-S Application Scenarios

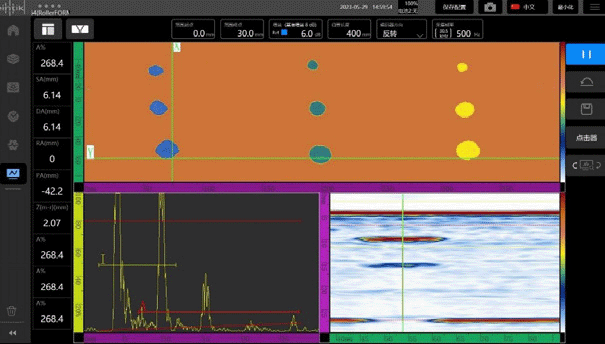

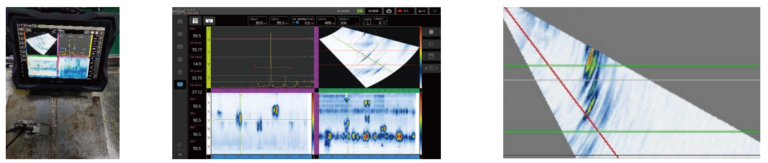

Weld Inspection

The Phaseye S is particularly suited for field weld inspections, offering flexible view layout settings. It supports single-beam C-scan and fused C-scan displays, single-beam D-scan, and fused D-scan displays, providing comprehensive defect information. The system automatically identifies defects and provides equivalent values, lengths, heights, and other relevant defect information.

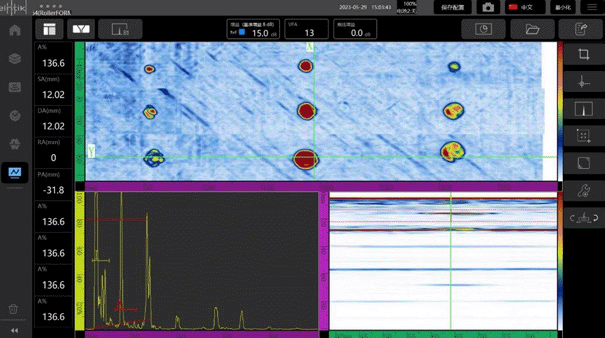

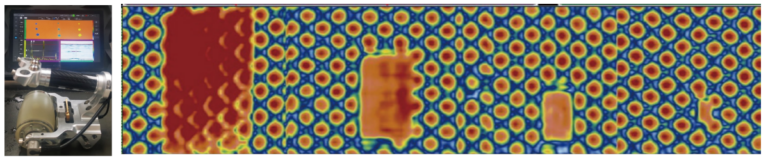

Composite Material Inspection

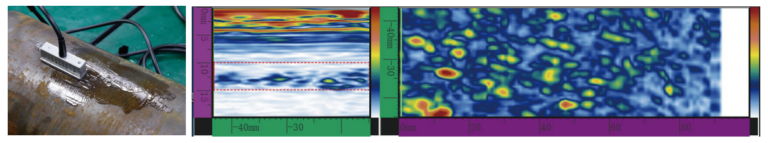

The Phaseye S, when used with corrosion detection probes, is highly suitable for in-service inspection of corrosion in containers and pipelines. It is capable of obtaining internal corrosion profile information and determining the minimum remaining wall thickness. This enables accurate assessment of the remaining service life of containers and pipelines. A C-scan image provides a map of the corrosion distribution over the entire scanned area.

Corrosion Detection

The Phaseye S, combined with a roller probe, is a cost-effective solution for composite material inspection. The roller probe is convenient to operate, and the Phaseye S is portable and compact, making it particularly suitable for on-site maintenance and inspection of composite materials. It can detect various types of composite materials and also has a good detection effect on honeycomb composite materials.

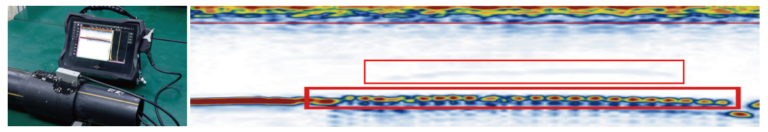

PE Pipe Electrofusion Welding Inspection

The Phaseye S, used in conjunction with PE pipe electrofusion welding inspection probes, is suitable for on-site inspection of PE pipe welding. It is portable and convenient, capable of clearly displaying signals from each resistance wire. The quality of the welding can be assessed based on the resistance wire signals, and the depth of fusion can be determined through the signal images of characteristic lines.

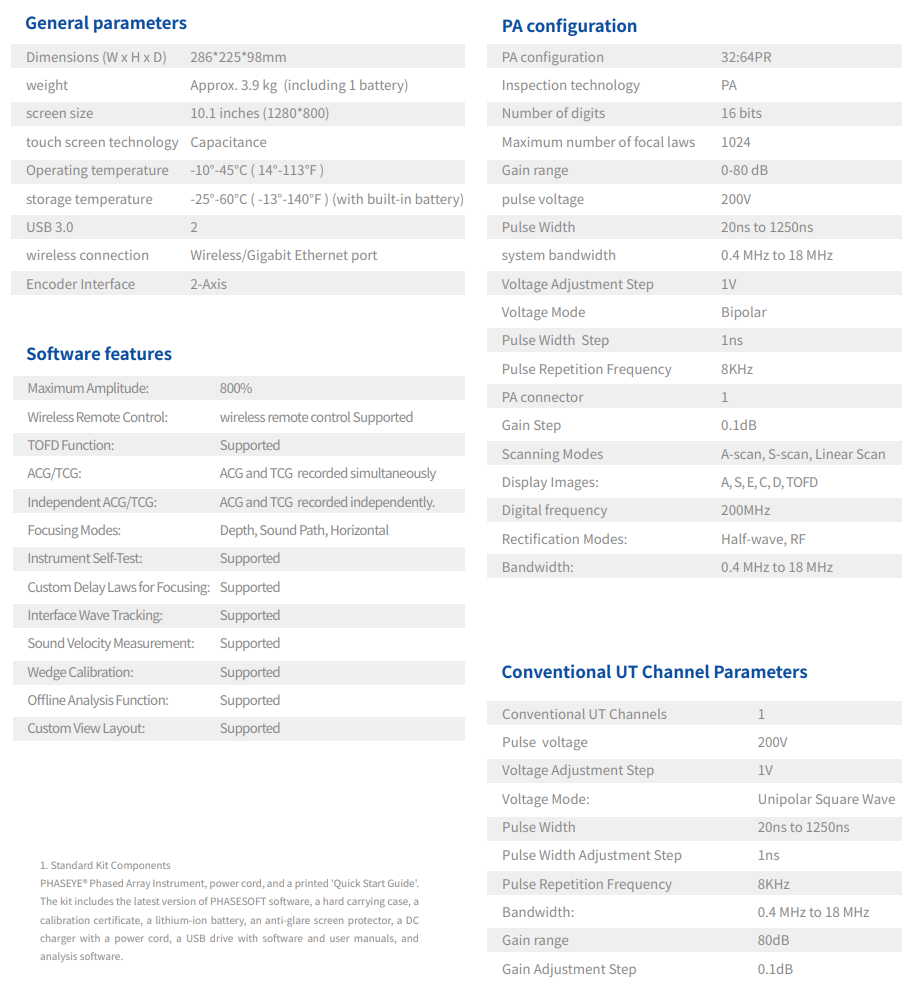

PHASEYE-S Specifications