PHASEYE - FMC 64

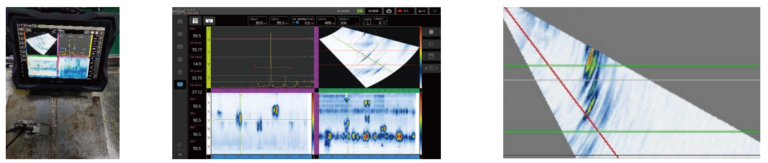

The PHASEYE 64:128PR flaw detector with full matrix capture (FMC), total focusing (TFM), and 3D display

- Water-cooled plate detection.

- Wind turbine blade inspection.

- Pull Extrusion Plate Testing

- Composite material testing.

- HDPE pipe inspection

- Honeycomb bonding inspection

- Bolt inspection

- New energy battery testing

- Train wheel and axle

PHASEYE PAUT 32-128PR FMC | TFM

Eintik full matrix acquisition phased array flaw detector 64/128PR

PHASEYE FMC-64 phased array flaw detector is a full matrix acquisition phased array flaw detector 64/128PR. Its internal thermal conductive material adopts aerospace technology to achieve a compact design. At the same time, the fuselage adopts highly reinforced The aluminum alloy shell is sturdy and durable with excellent shielding; it is also equipped with a high-definition and bright widescreen large-size industrial capacitive screen, making detection easy whether indoors or outdoors. The device is equipped with up to two large-capacity hot-swappable lithium batteries for power supply, which can meet the normal working use of 5 to 8 hours a day.

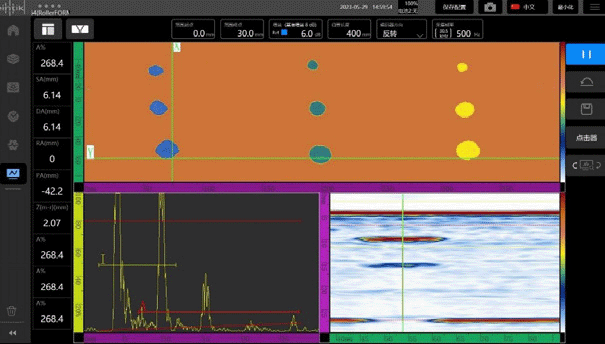

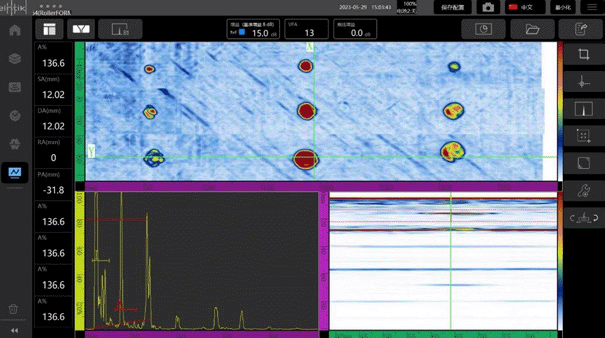

PHASEYE SOFT

Provide fast, efficient, real-time 3D imaging capabilities

PHASEYE FMC-64 is a powerful flaw detection instrument that combines FMC, TFM and PA. The PHASESOFT software allows the detection efficiency and capabilities to be fully reflected. It has complete data processing and reporting functions, especially for TFM and PA data. In terms of processing, data is at your fingertips and defects have nowhere to hide! The system has added a variety of display modes, including A, B, C, S and 3D imaging, etc., making the image closer to the real workpiece and making the inspection more intuitive and clear!

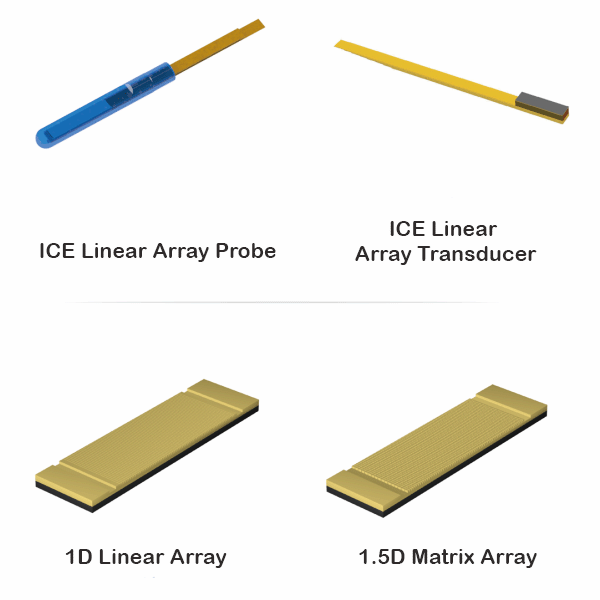

Integrated design of probe and instrument

In the early stages of instrument design and development, we combined our own comprehensive probe R&D and manufacturing capabilities to comprehensively improve the consistency and comprehensive performance of the PHASEYE FMC series phased array products. Aintik can provide you with professional industrial ultrasonic application development, from professional software to special probes, from encoders to scanning frames, we provide integrated solutions!

PHASEYE-S Application Scenarios

Weld Inspection

The Phaseye S is particularly suited for field weld inspections, offering flexible view layout settings. It supports single-beam C-scan and fused C-scan displays, single-beam D-scan, and fused D-scan displays, providing comprehensive defect information. The system automatically identifies defects and provides equivalent values, lengths, heights, and other relevant defect information.

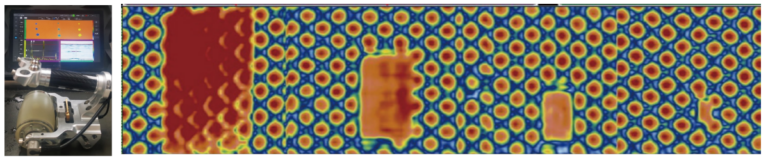

Composite Material Inspection

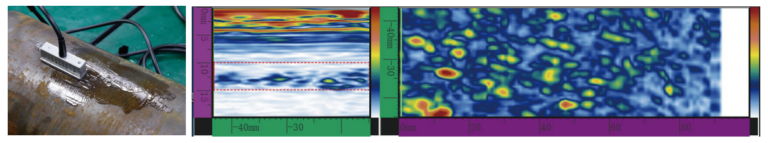

The Phaseye S, when used with corrosion detection probes, is highly suitable for in-service inspection of corrosion in containers and pipelines. It is capable of obtaining internal corrosion profile information and determining the minimum remaining wall thickness. This enables accurate assessment of the remaining service life of containers and pipelines. A C-scan image provides a map of the corrosion distribution over the entire scanned area.

Corrosion Detection

The Phaseye S, combined with a roller probe, is a cost-effective solution for composite material inspection. The roller probe is convenient to operate, and the Phaseye S is portable and compact, making it particularly suitable for on-site maintenance and inspection of composite materials. It can detect various types of composite materials and also has a good detection effect on honeycomb composite materials.

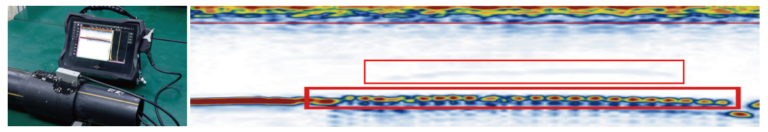

PE Pipe Electrofusion Welding Inspection

The Phaseye S, used in conjunction with PE pipe electrofusion welding inspection probes, is suitable for on-site inspection of PE pipe welding. It is portable and convenient, capable of clearly displaying signals from each resistance wire. The quality of the welding can be assessed based on the resistance wire signals, and the depth of fusion can be determined through the signal images of characteristic lines.

The new ultra-high performance architecture

- 300Gb DDR bandwidth makes real-time full aggregation (TFM) operation smoother and smoother

- The ultra-high dynamic range of the 100MSPS/16bit ADC makes details clearer

- Proprietary circuit design greatly reduces transmission and reception losses and achieves ultra-high signal-to-noise ratio

- Built-in new focusing law calculator with independent intellectual property rights to achieve 3D simulated sound field distribution

- The emission voltage of up to 200V enables perfect detection of precision micro workpieces and large workpieces.

- Synchronized 64/128 hardware channels to meet various complex application requirements such as special area arrays and double-area arrays

- FMC data collection speed can reach 2GB/S, making data collection more efficient and detection more comprehensive.

- Multiple machines can be used in parallel to realize large-scale system function applications.

More Functions

- Full matrix acquisition (FMC) – up to 128 array elements, acquisition speed up to 2GB/S

- Total Focus Technology (TFM) – Real Time, high efficiency and high resolution

- Built-in Focus Law Calculator (FLC)-3D simulation technology predicts sound field distribution

- Multiple hardware configurations to meet different detection needs-32:64PR 32:128PR 64:128PR, etc.

- Aintic full matrix acquisition phased array flaw detector 64/128PR

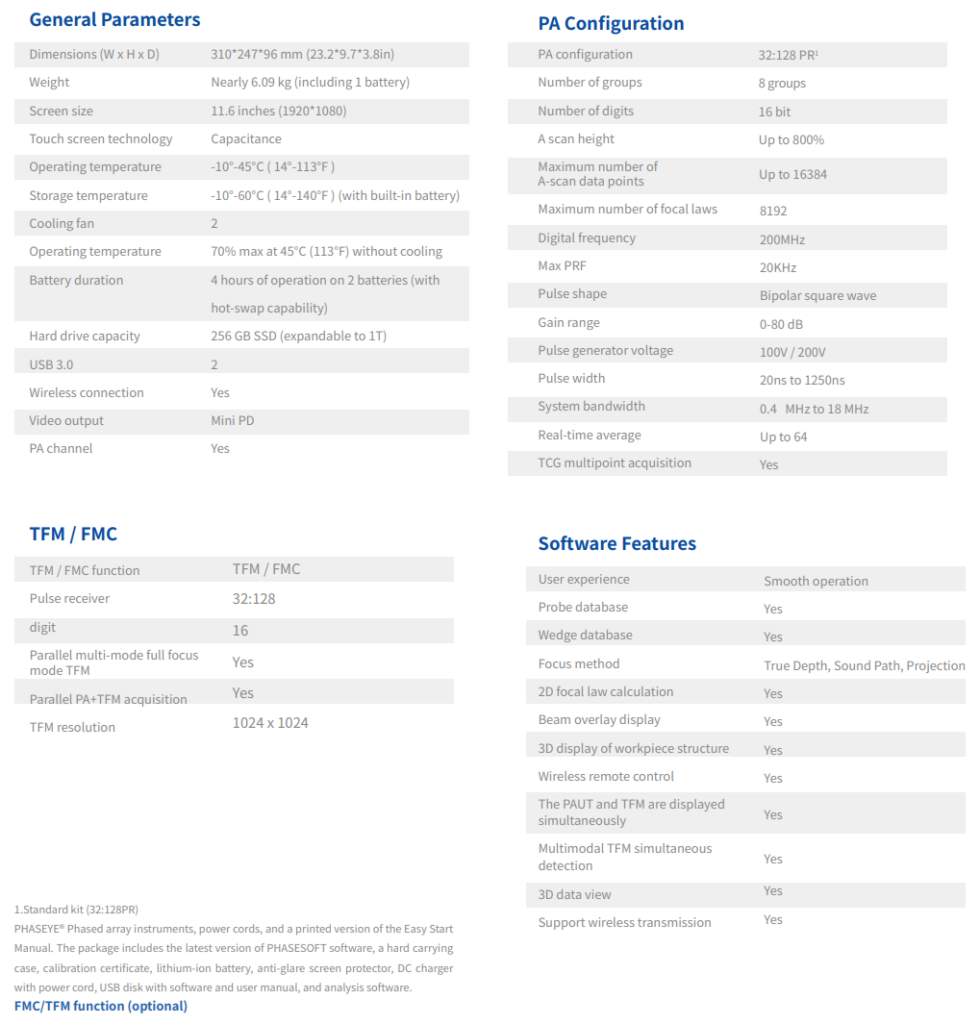

PHASEYE Specifications