Seeking Partners

Contact Us

Solutions

- PHASEYE PAUT FMC | TFM

- Automotive Spot Welds

- PAUT Probes & Transducers

- Automated NDE Inspections

- Wind Turbine

- Friction Stir Welds (FSW)

- HDPE Pipe Welds

- Bolt Inspection

- Composite Materials

- Honeycomb Bondings

- EV Batteries

- Turn Key Solution

Download Center

Why Partner With Eintik?

Delivering Advanced NDE Solutions Through Our Partnership

- High-Profit PAUT Systems: Leverage advanced technology for superior results and profits.

- Comprehensive NDE Solutions: Full spectrum of inspection services.

- World-Class Manufacturing: 5K m² factory In-house production of probes and transducers for unmatched reliability and performance.

- Competitive Pricing: Exceptional value that enhances your offerings.

- Full In-House Design: From system to software, every product—including our advanced probes and transducers—is meticulously designed in-house, ensuring seamless integration and peak performance.

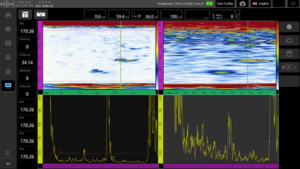

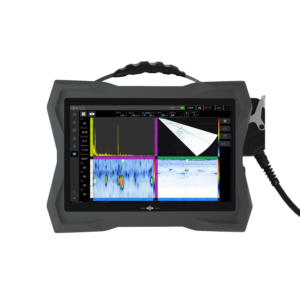

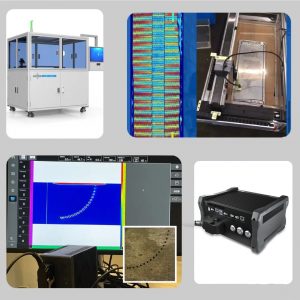

PHASEYE | PHASELINK PAUT 32:128 FMC TFM Systems

Introducing the PHASEYE FMC-64, a pinnacle of innovation in the phased array flaw detection realm. This device stands as a testament to cutting-edge engineering, marrying form and function in a compact, robust design. Ideal for discerning partners seeking reliability and precision, the PHASEYE FMC-64 embodies the future of flaw detection technology.

Key Features:

- Full Matrix Capture Technology: Employs 64/128PR for comprehensive flaw detection.

- Advanced Features:

- Full Matrix Capture (FMC) – up to 64 elements capture at 2GB/S

- Built-in Focal Law Calculator (FLC) – 3D simulation technology predicts sound field distribution

- Available as 32:64 PR, 32:128PR, 64:128PR

- User-Friendly Interface: Ensures ease of use in demanding field conditions.

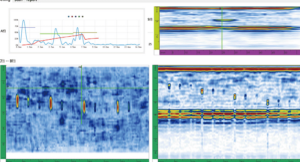

NextSPOT Automotive Spot Weld Flaw Detector Series

Engineered with the automobile industry’s unique needs at its core, the NextSpot 600 ultrasonic flaw detector is the quintessential tool for identifying imperfections within spot welds. Encased in a rugged, lightweight aluminum housing and shielded by weather-resistant rubber, this device epitomizes resilience and portability. Through the lens of patented technology and a legacy of R&D, it offers precise, real-time imaging, making it an indispensable ally in maintaining the highest standards of quality and safety in automotive manufacturing.

Core Advantages:

- Automobile Industry Precision: Specifically designed for detecting spot weld flaws in automotive applications.

- Robust and Portable: Crafted from a single piece of aluminum with a protective rubber coating for durability in diverse environments.

- Immediate Visualization: Real-time imaging capabilities enhance the inspection process.

- Streamlined Efficiency: Features a user-friendly interface, optimizing time and productivity on the production line.

Factory: In-House Probes Manufacturing (Industrial & Med)

Our newly inaugurated 5,000 sqm probe factory stands at the forefront of innovation, equipped to manufacture both industrial and medical probes. This expansion not only elevates our in-house capabilities but also ensures we meet the diverse NDT needs of all our customers, providing solutions that are as unique as their challenges.

Our latest probe factory video

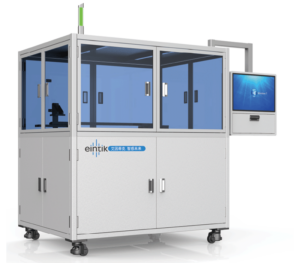

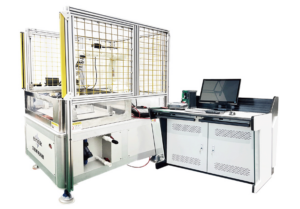

Full Turnkey Automated Robotic NDE Inspections

The automated NDE inspection system represents a leap forward in the realm of flaw detection, offering a comprehensive, turnkey solution powered by advanced robotics and PAUT technology. Designed to meet the intricate demands of diverse industries, this system excels in delivering precise, reliable inspections across a wide range of applications. From the towering turbines that harness the wind to the intricate bondings within composite materials, this system ensures integrity and safety with unparalleled efficiency.

Key Applications:

- Wind Turbine Inspections: Ensures the structural integrity of wind turbines, crucial for renewable energy generation.

- Friction Stir Welds (FSW): Offers detailed inspection of high-quality welds in challenging materials.

- HDPE Pipe Welds: Specializes in the examination of high-density polyethylene pipe welds, essential for utilities and infrastructure.

- Bolt Inspection: Provides critical assessments of bolt integrity in various structures.

- Composite Materials: Evaluates the composition and bonding of advanced composite materials.

- Honeycomb Bondings: Inspects the unique structures of honeycomb bondings in aerospace and beyond.

- EV Batteries: Ensures the reliability and safety of electric vehicle batteries through meticulous inspection.

- Turnkey Solution: Delivers a comprehensive, ready-to-deploy system for diverse NDT needs.