Oil and Gas Pipeline

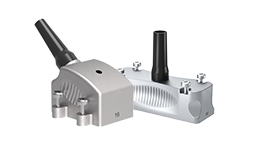

Phased array probes, testing instruments and equipment, testing solutions, ODM customization. . .

Oil, Gas and Pipeline Inspection Solutions

With our innovative R&D team and world-class manufacturing facilities, you can trust us to provide best-in-class products and services for oil, gas and pipeline inspections. Our state-of-the-art phased array, UT, TOFD probes, scanners and wedges, as well as Eintik intelligent inspection systems and instrumentation, can improve your inspection performance, accuracy and more competitive cost savings.

Whether your application is extracting oil and gas from the ground (upstream), safely transporting it around the world (midstream), and ultimately converting these resources into fuels and finished products (downstream), we have the solutions to detect it . If there is no suitable reference case, our team can help you design and customize a solution that is more suitable for your application from concept.

Up Stream

Main Application

Pre-Operation Inspection:

- Riser weld

- Large forgings

- Cladding quality

- Drill pipe

- Ordinary weld

Pre-Operation Inspection:

- CRA weld

- Ordinary weld

- Riser bolts and inserts

- Riser corrosion

- Riser weld

Mid Stream

Main Application

Pre-Operation Inspection:

- Storage tank

- Ordinary weld

- Girth weld

- Pipe manufacturing

Pre-Operation Inspection::

- Long weld

- Corrosion

- CRA weld

- Ordinary Weld

Down Stream

Main Application

Pre-Operation Inspection:

- Ordinary weld

- Access to restricted welds

- Single sided weld

Pre-Operation Inspection:

- Corrosion mapping

- CRA weld

- Ordinary weld

- Access to restricted welds

- Single sided weld

- Carbon steel pipe

- Dome top